Automatic 6 Wheels Linear Trigger Capping Machine

VKPAK 6 wheels capping machine are machines used to apply trigger pumps on medium and high productions, with a speed range that can vary from 10 up to 200 BpM. These trigger capping machines are designed to apply trigger pumps although they are extremely flexible and versatile and are able to work different kinds of closure. They are also modular as they can be integrated with different new bottles and caps at a later time.

As all VKPAK capping machine, these trigger capping machines are completely customizable according to customer’s requirements: for example, the layout of the capping system is adapted to customer’s facilities, the machine can work clockwise or anticlockwise, cap feeder may be placed beside, in front or behind the machine. The capping machines are suitable to work different kind of containers, from smallest to biggest ones.

Description

- Automatic 6 Wheels Linear Trigger Capping Machine adopt the mode of one motor controls one capping wheel, which can ensure the machine to work stably and keep consistent torque under long term working condition

- The clamping belts can be adjusted separately, which allow the machine to suitable for capping bottles with various heights and

shapes - If you choose the optional cap guiding system together with the machine ,it will then also fit for pump caps

- The convenient construction adjustment system is equipped with precious ruler and counter

- Automatic spindle Bottle Capper Machine can be lifted and descended automatically by a motor.

Packaging Type: Bottles

Packaging Material: Wood

Type: Capping Machine

Condition: New

After-sales Service Provided: Free Spare Parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support, Engineers available to service machinery overseas

Place of Origin: China

Brand Name: VKPAK

Voltage: 220V 50HZ

Application: Beverage, Chemical, Commodity, Food, Medical, Machinery & Hardware, Apparel, Textiles, automatic screwing cap machine on the bottle

Weight: 500KG

Certification: CE

Driven Type: Electric

Dimension(L*W*H): 1250*850*1750mm

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Name: automatic Trigger Spray Capping Machine

Model: VK-SC

Brand: VKPAK

Usage: use for capping or screwing bottles

Function: capping

Capping speed: 50-200bottle/min (subject to bottles and cap)

Material: 304/316 Stainless Steel

Technical Parameter

| Name Model | VK-SC Automatic linear spindle capping machine | |

| Capacity | 0~200b/m(subject to bottles and cap size) | |

| Bottle and Cap Diameter | Φ20~120 no need to change any molds for different caps | |

| Bottle Height | 40~460mm | |

| Machine Dimension | L1060*W896*H1620mm | |

| Voltage | AC 220V 50Hz | |

| Power | 1500W | |

| Weight | 500kg | |

| Cap Feed System | Cap elevator | Vibrator cap feeder |

| Dimension | L880×W1000×H2600mm | 800×600×1700mm |

Detail Images

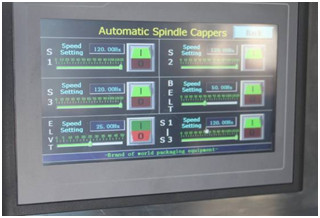

Touch Screen

Touch Screen

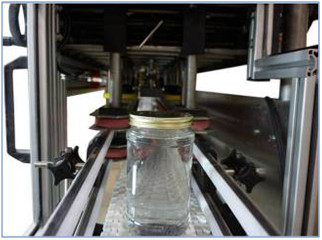

- 3 Couple of wheels for capping

- Each Wheel is individually adjustable

- The wheels can run in opposite direction to make cap fitting bottles well if necessary.

- The two-belt height is adjustable to fit different sizes of bottles.

- The capping wheel is soft to prevent caps from damage

- The capping wheel is horizontally adjustable for different sizes of caps

- The capping wheel is vertically adjustable for bottles of different heights

9 Motors

6 motors for 6 capping wheels

2 motors for bottle clamping belt

1 motor for machine up and down

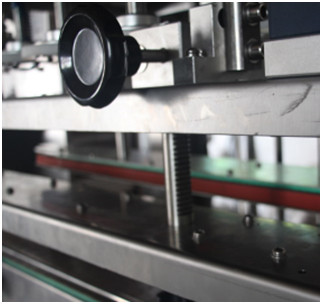

Meter Index for Mechanical Adjustment

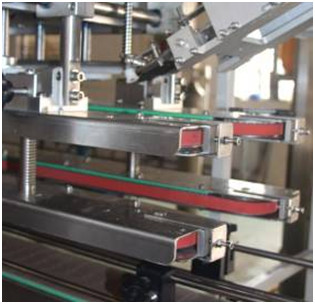

Two Level Clamping Belts

Easy Adjustment between each level

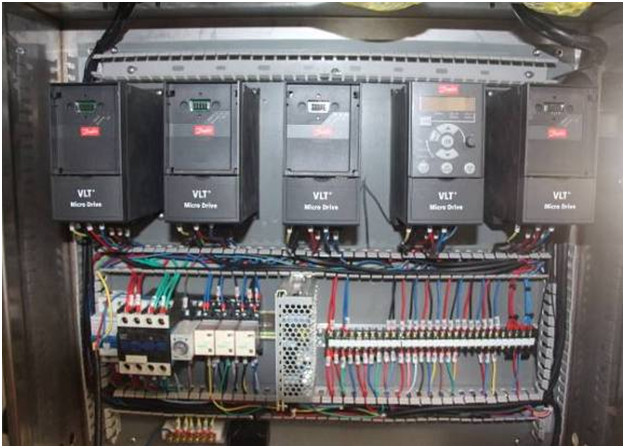

5 Danfoss Frequency Converters

Schneider Relay

Main Features:

- Power height adjustment

- Comprehensive universal cap chute and escapement

- Hand-wheel operated

- Gripper Belt height and width adjustment

- Variable speed AC motors 4, 6 or 8

- Spindle Wheels Spindle Wheel adjustment knobs, with lock nut hand wheel

- No change parts required for a wide range of containers

- Sanitary 304 stainless steel drive shafts and adjustment support shafts

- Timing belt power transmission for Spindle Wheels

- Bottom screw changeover on Spindle Wheels

- 1/2” aluminum mounting plates and 1/2” hard coat anodized supports on Cap Feed Chute

- Designed for easy integration with most conveyor configurations (sold separately)

- Intrinsically Safe

- Removable dual gripper belts

- Trigger spray cap rails

- Special electrical requirements