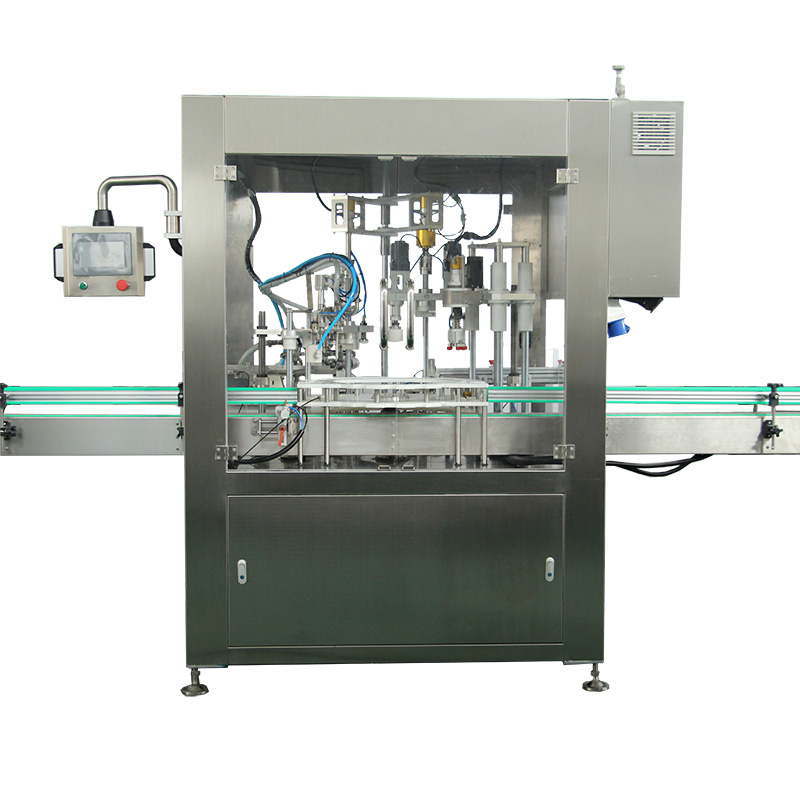

Liquid Filling Machine

VKPAK manufactures a range of standard liquid filling machines to suit a wide variety of liquids, bottle sizes and production outputs. For businesses ranging from SME’s through to large multinationals, our machines can be used for a wide spectrum of applications.

Our liquid filling machines usefully automated multi-head filling systems using either vacuum level filling or volumetric piston filling technologies. If you cannot find a suitable machine in our standard range, please contact us to discuss your individual requirements – our engineering team is on hand to discuss modifications or even bespoke machine design solutions.

Liquid Filler Systems & Liquid Filling Equipment

VKPAK is the leading provider of inline liquid filling machines and liquid packaging machinery in China, offering a wide variety of fillers with fully automatic functions. We have both gravimetric and volumetric liquid fillers available for various industries from food and beverage production to industrial and corrosive product production.

Our automatic filling machines range in size from portable table top machines to industrial size liquid packaging systems – whatever is needed to get your job done. View our liquid fillers below, and don’t hesitate to contact us for more information on our products.

When it comes to your liquid filling needs, rely on VKPAK to help you determine the best packaging system for your business. Contact us today for a free consultation.

Use Our Liquid Filling Machines Expertise

System based on your needs. Our experts oversee every step of the design, manufacturing, instructions and installation of your equipment.

A Variety Of Bottle Fillers

Piston FillersGravity FillersPump FillersOverflow FillersCorrosive Fillers

Piston fillers are great option for packaging liquids. They offer fast and accurate fill rates, versatility with the ability to handle many different types of products, and they’re gentle on products. This filling machine is best suited for viscous products that are paste, semi paste, or chunky with large particulates. Piston fillers are primarily built to meet food grade standards and commonly fill heavy sauces, salsas, salad dressings, cosmetic creams, heavy shampoo, gels, and conditioners. Thy are also used for viscous chemical preparations like paste cleaners and waxes, adhesives and epoxys, heavy lubricant oils and greases.

The machine works by a simple principle; The piston is drawn back in its cylinder so that the product is sucked into the cylinder. A rotary valve then changes position so that the product is then pushed out of the nozzle instead of back into the hopper. The volume of the product that is sucked into the cylinder is the precise volume that will be dispensed into the container.

The advantage of this type of filling machine is that involves conventional mechanical technology that is easy to understand for most users. It is also the most cost effective, accurate and fastest way to fill fairly thick products. it costs less than the servo pump filler is still the most cost effective filling machine for thick products.

The Gravity Fillers are suitable for bottling virtually any water-thin to medium consistent viscosity liquid. Gravity fillers are ideally suited for thin, foamy products where gravity fillers handle heavier viscosity products.

VKPAK offers several different types of pump fillers to accommodate a wide variety of products. They provide an accurate and versatile method for filling low, medium and high viscosity liquids into a wide range of containers. VKPAK uses a variety of pumps including progressive cavity pumps, gear pumps, lobe pumps, rotor pumps or whichever is best for the application. We work with each customer to choose the right pumps, valves, and fittings for each application.

Overflow fillers provide the same cosmetic fill level, making them ideal for filling transparent containers that must have a consistent fill level. Gravity and pressure overflow fillers are designed to handle thin to medium viscosity products. The VKPAK overflow filler is used for specialty filling applications and is typically used to fill small volume glass containers with low viscosity liquids.

VKPAK Poly Fillers, machined completely out of HDPE, are designed to handle the punishment of a highly corrosive environment. Using 1/100 second timers on each individual fill head offers simple adjustment and extreme accuracy. The fillers are designed to fill from a fraction of an ounce to five gallons and are capable of handling viscosities ranging from thin and foamy to very thick liquids.

Benefits Of Using Our Automatic Filling Machines For Packaging Liquids

VKPAK offers some of the best liquid filling machines available for products of all types. The versatility of our equipment makes them compatible with many different applications, depending on your specific system requirements.

Features include:

- Our inline liquid filler machinery systems come in a variety of sizes from 1-16+ head inline fillers.

- Options for hazardous, corrosive or sanitary environments

- Custom built for your specific application and budget

- Robust construction–built to last

- Designed for product versatility

- Minimal downtime for maintenance & cleaning

- Easy setup with quick changeover features

- Optional Configurations

VKPAK manufactures a complete range of sanitary fillers to meet a wide variety of applications. All sanitary fillers are designed with quick breakdown fittings, valves and pumps to be used where needed. All reservoirs have flanged quick disconnect fittings so that the fillers can be easily and thoroughly cleaned.