Liquid Filling Line

VKPAK offers liquid filling systems for just about any product on the market. The correct liquid filling system for your product will depend on a number of different factors, including the viscosity of your product and your production needs. Liquid fillers are manufactured with different filling principles based on the product being filled. In addition, these packaging machines will be manufactured at different levels of automation to meet your production needs.

The filling principle used on the liquid filling system designed for your product will be determined mostly by the product itself as well as the product container. A thin, free-flowing liquid will use a different filling principle than a thicker, more viscous product.

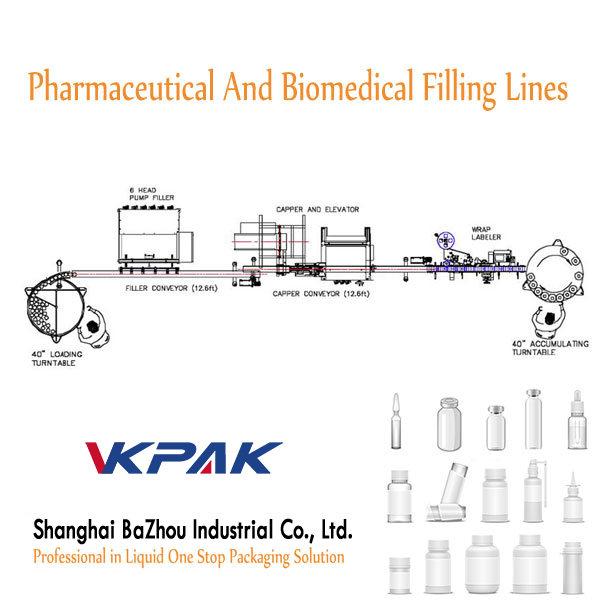

Generally complete liquid filling line, including the three main parts of the filling machine, capping machine, and labeling machine and other auxiliary equipment. Common auxiliary equipment includes: bottle unscrambler, bottle washer, cap unscrambler, cap lifter, vibration plate, coder, aluminum foil sealing machine, etc.

VKPAK is a professional one-stop solution provider for liquid packaging, which can provide you with various liquid and paste filling solutions.