Automatic Servo Motor Bottle Filling Machine

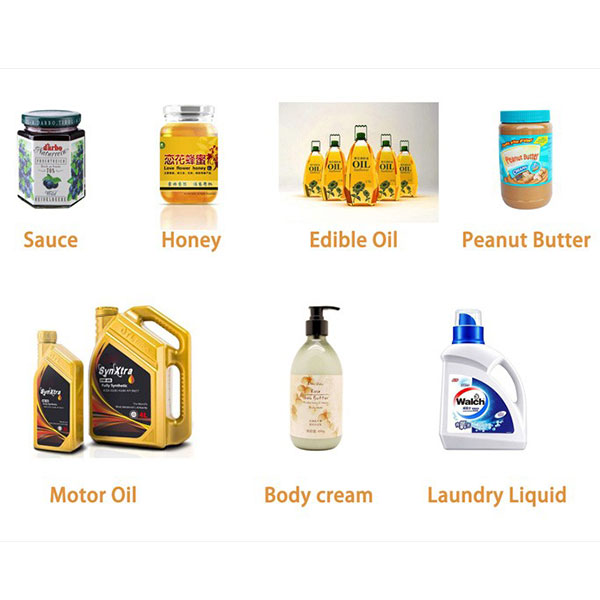

The machine was design and manufactured by VKPAK, especial for liquid from thin viscous to high density liquid, such as water, edible oil,lube oil, lotion, cream, Jam, sauce, honey, ketchup and so on. It is mostly used in the industry of chemicals, foodstuff and pharmaceuticals.

The filling system is driven by servo motor which assure high filling accuracy. It is controlled by the PLC, human interface and easy operation.

Description

Automatic servo motor bottle filling machine from VKPAK can fill up to 16 containers at the same time with virtually any product from thin and foamy to thick and stringy. It is recommended for a wide variety of products including cosmetics, personal care, food and beverages, chemicals, pharmaceuticals and more.

Packaging Type: Barrel, Bottles, Cans, Capsule, Cartons, Stand-up Pouch

Packaging Material: Glass, Metal, Paper, Plastic, Wood, Other

Type: Filling Machine

Condition: New

After-sales Service Provided: Online support, Video technical support, Free Spare Parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas

Place of Origin: Shanghai, China

Brand Name: VKPAK

Voltage: 220V/380V

Application: Apparel, Beverage, Chemical, Commodity, Food, Machinery & Hardware, Medical, Textiles

Weight: 1200kg

Certification: ISO9001

Driven Type: Mechanical

Dimension(L*W*H): 2500*1400*2500mm

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Printing Shops, Construction works , Food & Beverage Shops, Advertising Company

Name: chemical filling machine

Contact Material: 316SS

Control: Servo Motor control filling volume

Processing Types: Filling liquid filling into bottle

Filling volume: 1000ml-5000ml and 100ml-1000ml

Shampoo : diving filling avoid-form

Honey: anti-silk and shut-off filling nozzle, heated double jacked hopper& piston with mixing system.

Lube oil : anti-drip, vacuum suck filling nozzle.

Edible oil : anti-drip, vacuum suck filling nozzle.

Ketchup : anti-silk and shut-off filling nozzle, heated double jacked hopper& piston with mixing system.

Technical Parameter

| Name | Automatic servo motor bottle filling machine |

| Model | VK-PF |

| Filling Nozzles | 2-12 nozzles, or customized |

| Power | 2.5KW |

| Applied bottle range | 30-100ml, 100-1000ml, 900ml-5000ml |

| Filling Accuracy | ±0.1% |

| Filling speed | 800-4200 bottles/hour , 30b/min per 4 filling nozzles 1L |

| Dimension | 2200*1400*2300mm |

| Weight | 400kg |

| Power supply | 220V Single phase 50HZ 380V Three phase 50HZ |

Main Features:

- Easy to adjust the filling volume, automatic adjust by touch screen, high accuracy and stable Speed.

- Linear type filling system is easy to adjust for many different types of bottles

- Easy to maintain, no special tools are required.

- No bottle, no filling, automatic PLC control

- blocked Filling nozzles are anti drops, silk, and auto cut viscous liquid

- Accurate filling volume, within ±0.5-1% and a total bottle counter.

- Special seals or hoses are adapted if the liquid are corrosive.

- Diving nozzles for bottom up filling of foaming products if need

- Bottle mouth can be located

This machine adopts cylinder transmission, enduring the stability of the equipment, accuracy. All the action of filling, entering, filling, outing and etc can use the search unit tail automatically, besides the detect, control, have no bottle and filling action. If change the shape of bottle, just need adjust the convey belt protect hinder, the hinder bottle board, and the distance of filling heads. Simple and convenient, one machine can used many kinds of bottle.

The filling heads designed for many heads (can be designed depend on the product capacity), will not be break the machine when the speed is high or act quickly. The filling parts adopts piston pump, use many measuring pump separately control the filling quantity, the measuring pump can change the quantity according to the request, measuring accuracy, filling steady, high speed, suit for multitudinous product. When the bottle enter to filling by the convey belt, the opto-electrical measure the number of bottle automatically, and filling heads fall to filling automatically, and there is cut-off valve installed, when finish the filling, filling heads replacement, the cut-off valve close, can solve the water-clock problem effectively, high effect, good stability.

Detail Images