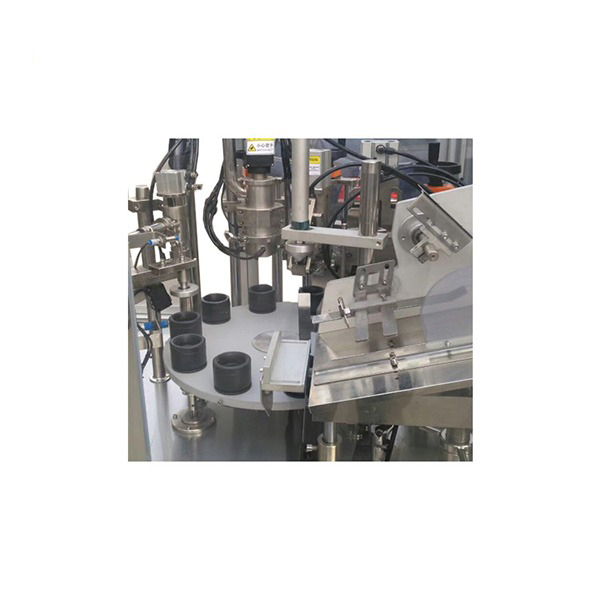

Semi Automatic Tube Filling Sealing Machine

Semi-automatic tube filling and sealing machine is used for filling of polyethylene and laminated tubes with gels, creams or other fluids, sealing them with hot air, stamping date and / or batch No. and cutting excess plastic on the tube ending, which arises during the tube sealing.

This machine is made of stainless steel, adopts pneumatic system, the filling volume and speed can be adjusted easily. Except put the empty tubes by hand, all the workstages, such as, filling, sealling, cutting, printing codes, etc, are done by the machine automatically. This machine can fill various liquids, skin care cream, paste, sauce, ketchup, jam, mustard, ointment, medicine paste, tooth paste, etc. into plastic tubes or laminated material tubes and seal.

Description

Possible application of the cheap tube filling and sealing machine:

The cheap semi-automatic tube filling and sealing machine is used for packing of cosmetics, pharmaceuticals, chemicals and food products into tubes. The budget tube filling and sealing machine is designed to handle small and medium size batches / production lots / jobs. It can be used for regular production or for labs.

VKPAK – manufacturer of manual tube filling and sealing machines

VKPAK is a manufacturer of manual tube filling and sealing / crimping machines for thermoplastic (polyethylene (PE), laminated and other plastic) and aluminum tubes. Contact us to receive a price quotation. We do not trade with used machines / equipment, however we are convinced that you will find the prices / pricing of our new machines very attractive.

| Name | Semi Automatic Tube Filling Sealing Machine |

| Tubes material | Laminated material, or PP, PVC, etc. |

| Products | Liquid, cream, or paste |

| Volume | 10-450ml |

| Filling | Cylinder pump |

| Precision | ±1% |

| Tube size | Caliber:15-50mm, length 50-220mm |

| Pneumatic | 0.6-0.8Mpa, 0.2 CBM/min |

| Capacity | 20-35 pcs/min (Up to the size of the tubes and the filling volumes in each tube) |

| Voltage | AC220V, 1 phase, 50/60Hz. |

| Power | 3.3Kw. |

| Material | Stainless steel 304 |

| G.W. | 450Kg. |

| Dimension | L1250*W1050*H1600mm |

Features

1). With both tubes inner wall and external heating devices, ensures each tube tail sealed firmly, with high speed;

2). With SUNX or SICK mark locating sensor, can always seal the tubes at the same fixed position precisely;

3). Bucket with stirrer, can work with various liquid or cream, paste products;

4). Advanced SIEMENS PLC and touch screen operate system, easy to operate;

5). With graduator, ensures the rotary plate with the 8 (or 10) tubes can turn a precise same angle or circular distance each time;

6). With embossing codes, can make date or batch codes on each tube tail automatically;

7).With circulating water chiller, can cool down the tails of the tubes after sealing, assure the tails sealed firmly and beautiful;

8). With shears device, can trim the sealed edge automatically, ensures every tube with uniform and beautiful tail.

9). With high automation, except inset the empty tubes by hand, all the remaining work stages are finished by the machine automatically.

10). Finished tubes can spring into cartons or boxes, no need take them by hand.