There are many types of filling machines used to package the variety of products in today's marketplace including liquids, pastes, chunky products, powders, granules, tablets, capsules, etc. Most filling machines are available from semi-automatic tabletop versions all the way up to high speed production line machines, including rotary fillers. Even within categories of filling machines there are often many choices available, so we always encourage you to call or email us to make sure you are buying the exactly correct machine for your application(s). This article mainly introduces the types of liquid filling machines.

There are usually different filling types according to different filling standards.

According to the degree of automation, the types of filling machines are: manual filling machines, semi-automatic filling machines, and fully automatic filling machines.

Manual Filling Machines

These are manually operated and will need no power or electrical source. They are generally used for packing highly viscous liquids like creams, gels, and shampoos but will also suffice for medium viscosity liquids. Manual filling machines are ideal for small scale productions or laboratories where they will provide a higher output speed and increased accuracy than when the liquids are poured by hand. They are ideally used for filling vial and bottles with about 600ml capacities and have a production speed of 15-900 bottles/hour. This type of machine is not produced by VKPAK.

Semi-Automatic Filling Machines

These will be faster compared to manual machines and will suit medium and small scale production processes during a high-volume season. Semi-automatic machines are designed with nozzle, syringe and piston parts which guarantee they maintain a zero-drip operation. They can be used to package all types of liquids and those containing small food articles and even adhesives. Semi-automatic machines have filling ranges of 5-100ml and production speeds of 800 fills/hour.

Fully Automated Filling Machines

These are used for large-scale operations and in companies with high production needs. Automated filling machines are generally used with variable speed conveyor systems and for packaging, liquids with all levels of viscosity and those with suspended particles. Some manufacturers also configure their automated machines based on the type and volume of the filling container you are using for your product. You can also add filling heads on the machines to boost your company’s production rates. Automated filling machines can fill 5-10ml of a product and generate 6000 bottles/hour. We mainly produce this type of machine.

According to the filling principle, All liquid filling systems fall into either of two categories: volumetric or liquid level filling machines.

Volumetric Filling Machine vs. Liquid-Level Filling Equipment

There are very few bottles that don't have some small differences in volume. Considering that fact is very important in deciding the type of filling system you are going to use for your packaging. You've probably noticed at the supermarket or auto store that when you look at fill level, some of the bottles seem to look like they are short fills compared to others. Chances are they were filled with volumetric filling machinery. The volume inside the bottle is correct, but because of the small volumetric difference between the bottles it appears to be short.

With a liquid level filling machine all of the bottles will "appear" to have the same volume because the fill level will be the same, but in actuality there will be slight differences in fill volume, no short fills, but some slight overfills.

And so this is the decision you have to make beforehand: Volumetric or Liquid Level? For the vast majority of products the answer will be liquid level filling since it is cheaper and faster than volumetric filling, plus consumers of the product will not feel cheated when the bottles "appear" to be evenly filled. However volumetric filling is the best solution if the product has to have an exact dosage for it's use or if the product is very expensive per ounce and the little bit of giveaway could cost you dearly, especially in a high production environment.

Liquid Level Filling Machines

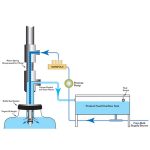

Siphon Filling Machinery

The simplest and probably one of the oldest technologies devised by man was the siphon principle. In this case we are talking about the siphon filling machine. Gravity flow into the tank to a valve that keeps the liquid level even, put some gooseneck valves up and over the tank side and back below the liquid level of the tank, start a siphon and voila, you've got a siphon filler. Add to that a little extra framing, and an adjustable bottle rest so you can set the fill level to the level of the tank and we now have a complete filling system that will never overfill a bottle, with no need for pumps etc. Our siphon filler comes with 5 heads (size is selectable) and can produce quite a bit more than many think possible.

Overflow Filling Equipment

In order to speed up the process of filling we have the pressure filling machine. Pressure fillers have a tank on the back of the machine with a valve to keep the tank full either by a simple float valve or by switching a pump on and off. The tank flood feeds a pump which then feeds to a manifold where a number of special overflow filling heads lower down into the bottle as the pump switches on forcing liquid into the bottles at a speedy rate. As the bottle fills to the top, and excess liquid goes back up a second port within the filling head and overflows back into the tank. At that point the pump switches off and any remaining excess liquid and pressure is relieved. Heads come up, bottles index out and repeat the process. Pressure filling machinery can be configured for semi-automatic, automatic in-line filling systems or as rotary pressure fillers for higher speeds.

Volumetric Filling Machines

Check Valve Piston Filler

Check valve piston filling machines use a check valve system that opens and closes on the infeed stroke and discharge stroke. A great feature of this type of filling equipment is that it can self prime to draw product directly from a drum or pail and then discharge into your container. Typical accuracy on a piston filler is plus or minus one-half percent. However check valve piston fillers do have certain limitations in that they cannot run viscous products or products with particulates as both can foul the valves. But if your products are free flowing (meaning they pour relatively easily) this is a great machine for startups and large producers as well.

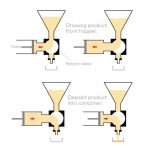

Rotary Valve Piston Filling Machine

Rotary valve piston fillers are distinguished by the rotary valve which has a large throat opening to allow thick products and products with large particulates (up to 1/2" diameter) from the supply hopper to flow through unimpeded. Great as a tabletop model or can be ganged for higher production requirements. Fill pastes, peanut butter, gear oil, potato salads, Italian dressing and much more on this type of piston filler with accuracy of plus or minus one-half percent. Fills accurately at a ten to one ratio of the cylinder set.

Pump Filling Machines

Pump fillers are another method of filling products ranging from liquids to thick pastes, even those with solid particulates (although generally much smaller than on a Rotary Valve Piston Filler). Available as tabletop models through multi-head ganged automatic machines. Another advantage of using positive displacement pump filling equipment is that the range of fill volumes is much greater than on a piston filler, albeit that the fill times increase significantly the larger the fill volume required. Other great features of a pump filling machine include easy fill adjustment by entering the amount needed, and a self priming feature similar to a check valve piston filler's ability to draw product directly from a drum or other container. For thicker products a supply hopper can be added similar to a rotary valve piston filler so that product flood feeds directly into the pump. Fill volumes are determined by counting revolutions (and partial revolutions) of the pump.

Peristaltic Pump Filling Machinery

Peristaltic pump filling machines are very popular in the pharmaceutical and hazardous chemical industries because product does not have any external environment exposure since the hose goes directly from the product supply, through the pump (as opposed to into the pump), and to the dispense point. When the product run is complete the hose can be disposed of, or treated for reuse. Furthermore with some pumps extreme accuracy is possible down to the 1 ul (microliter) level.

Timed Fill Gravity Systems

Timed flow fillers are another type of filling equipment on the market. This type of filler works on the principle of a tank mounted above filling heads that have solenoid valves to open and close for the flow, or in some cases pinching of the hose to close. Fill volume is determined by timers that open and close the valves or pinch the tubes. Single head models can work pretty well for a variety of products. Even multi-head models can work pretty well once the system is balanced if only one formulation is run or the flow characteristics are identical. However the big disadvantage of timed fill systems is when the user wishes to fill a variety of products with different flow characteristics. In this case the system needs to be rebalanced which is not an easy task as every adjustment of for one head's flow affects all of the others. Busch Machinery does not offer timed fill systems for this reason, as other machinery that we offer can offer the same or better accuracy, at about the same cost, and without the hassle associated with timed fill systems.

Net weight filling machines

Net weight filling machines use a weigh scale platform to monitor the weight of product as it is filling into a bottle or container. Net weight fillers are well suited for large container filling applications. This machine is used for weighing and filling 5-30kg liquid. Use photoelectric sensing, proximity switch and other sensing elements, so that it can be fully automated production. Using the submersible filling, filling valve diameter, fast feeding, valve mouth built-in plug, no drip leakage. Can do bottle filling, no bottle not filling. Stable operation, safe and hygienic.

Servo Driven Pump Fillers:

With the cost of servo drive controls coming way down over the last 10 years more and more uses for filling have come into play. Gear pump fillers is one type of application that has become very popular, although you must be sure that the pumps are sanitary pumps if you do foods, cosmetics or pharmaceuticals. The advantage of the gear pump is that you can fill almost any size product without need for change parts (although this still has limitations). At VKPAK we still think the jury is out on this, as piston fillers can still fill with as good or better accuracy, although with not quite as large a range..

Pressure Fillers:

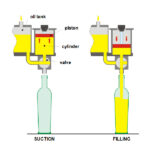

Pressure filling machines have their tanks below the bottom of the bottle. The tank flood feeds a pump (generally a centrifugal pump but also positive displacement pumps for thicker liquids) which then flows directly into the bottle until it reaches the fill level at which point excess product flow directly back into the tank. When filling plastic bottles the pump must be turned off (always for positive displacement pumps) before removing the filling tubes to allow the bottles to return to normal size (they swell under pressure) and drain off excess liquid. The big advantage of pressure fillers is that bottles fill more quickly so fewer heads (and space) are required and higher viscosity products can be filled. The disadvantage is that foamy products must be filled at slower pump speeds than normal, and this will work only if the foam settles out fairly quickly.

Counter Pressure Fillers:

These are liquid filling machines unique to the carbonated beverage industry which includes beer, soda and any sparkling beverage or wine. VKPAK does not sell counter pressure fillers, but we will still explain this complicated type of filler. The heads for this type of filling consist of 3 parts: Vent, CO2 pressurizer and fill tube. The head seals and the Vent and CO2 pressure valves are opened. The air in the bottle is forced out of the bottle and is replaced with the heavier CO2. The vent is then stoppered down and product from very specialized heads forces the chilled carbonated liquid down the sides of the container in a sort of swirl pattern to minimize foaming. Once the fill height is reached the vent completely closes at the same time the product is cutoff. Many people mistakenly think that the CO2 counter pressure is the carbonating process, but carbonizing is a bit more complicated than that. The purpose of the CO2 is to keep the already existing carbonized beverage in solution and to minimize foaming.