Automatic Orientation Position Labeling Machine

VKPAK manufacture of sticker labeling machine in Shanghai. Bottle Oriented Labeling Machine is for the round bottle and slove the trouble of manual labeler.

The customer will save manual cost and the speed is more higher. It is used in the Pharma , Chemical , Food industry and so on.

VKPAK is professional factory in any kinds of labeling machine (sticker labeling machine , glue labeling machine , sleeving labeling machine) . bottle oriented sitcker labeling machine is designed for the sticker label/ adheisve label , working for the round bottle , Tin can , Jars. Sticker wrap-around bottle oriented labeling machine,automatic locating taper bottle labeling machine.

Description

- Bottle Oriented Labeling Machine is controlled by servo motor ( label exact is 1mm), It is suitable for any kinds of round container .

- All the electrical parts of the labeling machine is made in Taiwan or Japan

- Three points holding mechanism allows high labeling precision for round bottle

- Pneumatic wrap-around station for versatile bottle diameter

Packaging Type: Bottles

Packaging Material: Wood

Type: Labeling Machine

Condition: New

After-sales Service Provided: Online support, Video technical support, Free Spare Parts, Field installation, commissioning and training, Field maintenance and repair service

Place of Origin: Shanghai, China

Brand Name: VKPAK

Voltage: 220v 50HZ

Application: Beverage, Chemical, Food, Medical

Weight: 300KG

Automatic Grade: Automatic

Certification: ISO9000,CE

Dimension(L*W*H): 2000mm*850mm*1450mm

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Printing Shops, Construction works , Food & Beverage Shops, Advertising Company

Name: orientation position labeling machine

model: VK-RPL

Labeling speed (pcs/min): 30-50 (relate to material and label size)

Labeling accuracy(mm): ±1.0mm(material and label sizes are not counted in)

Label size(mm): (L)20-300mm (H)30-180mm

Material size (mm): 20-120mm (H)40-200mm

Roll inside(mm): 76mm

Roll outer diameter(mm): Max:350mm

Machine size (mm): (L)2000*(W)850*(H)1450(mm)

Power supply: AC220V 50Hz/60Hz 1500W

Technical Parameter

| Name | Bottle Oriented Labeling Machine |

| Labeling Speed | 20-40pcs/min(Depending on label length and bottle thickness) |

| Height of Object | 30-200mm |

| Thickness of Object | 30-90mm |

| Height of Label | 15-140mm |

| Length of Label | 25-300mm |

| Label Roller Inside Diameter | 76mm |

| Label Roller Outside Diameter | 380mm |

| Accuracy of Labeling | ±0.5mm |

| Power Supply | 220V 50/60HZ 0.8KW |

| Gas Consumption of Printer | 5Kg/cm^2 |

| Size of Labeling Machine | 2000(L)×1000(W)×1250(H)mm |

| Weight of Labeling Machine | 150Kg |

- Suitable for round bottles fixed point and position labeling.

- Use rubber wheel differential spacing mechanism, inverter stepless speed change, separated into any spacing. No need change specifications parts when change products.

- Use imported well-known brand servo motor, ensuring high speed, precision, and stability.

- Using cylinder positioning, fast action and applicable for a wide range of product specifications.

- Rubber wheel rolling on labels, long service life. Positioning labeling is high precision labeling.

- Labeling accuracy ± 0.5 mm.

Configuration Parts

| Configuration Parts of labeling machine (VK-RPL) | |

| Description | Remark |

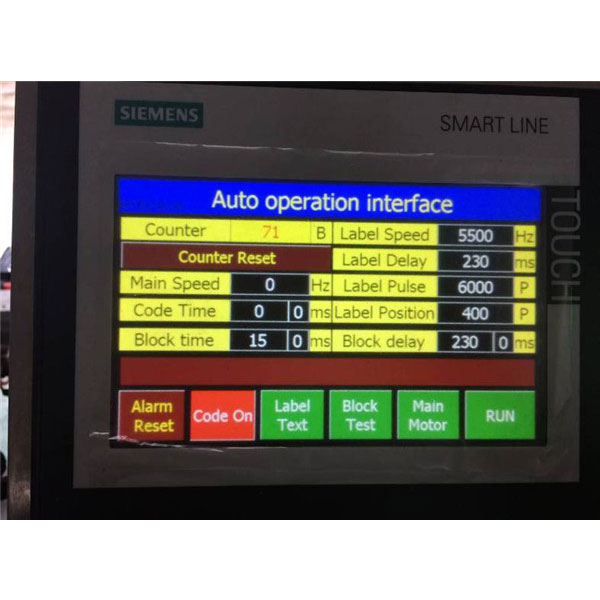

| PLC | Siemens |

| Touch Screen | Siemens |

| Transducer | Delta Made in Taiwan |

| DC24V Electrical Source | Delta Made In Taiwan |

| Checking label sensor | Keyence (Made in Japan) |

| Checking bottle Sensor | Keyence Made in Japan |

| Optical | Keyence Made in Japan |

| PANASONIC MOTOR AND DRIVER | Made in Japan |

| SWITCH | SCHNIDER FRANCE |

| Emergency Switch | SCHNIDER FRANCE |

Detail Images

Ribbon coding machine (print EXP MFG BATCH on the label)

- 1. A wide range of application, to meet the 10-100mm diameter range of cylinder labeling

- 2. Labeling accuracy is high, the tag end to end local deviation ≤ ± 0.5mm

- 3. Clever extrusion device material, simply put the workpiece, and auto-complete labeling

- 4. Card position adjustment, simple the different workpiece labeling switch

- 5. Timing belt traction, greatly improving the mechanical stability

Main Features:

- 1. Touch screen and PLC control

- 2. Around 30 memory recipes for labeling parameters easy for change bottle size.

- 3. Low or missing label detect.

- 4. Synchronized speed selection

- 5. Servo motor drive for high accuracy and high speed

- 6. No bottle no labeling.

- 7.Fixing hot foil coding machine , which can print EXP MFG BATCH on the label

Labeling machines are widely adopted in food, pharmaceutical, daily chemical industries for different label application. VKPAK offers orientation round bottle labeling machine for round, conical and polygon bottles high-precision orientating labeling.